Lay out the joints correctly

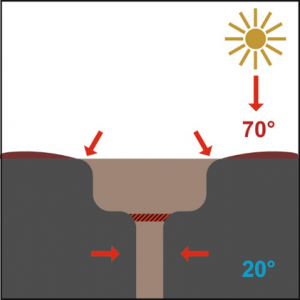

Deck properly To have a terrace you need some basic knowledge. Because mistakes often happen that you can avoid. A right joint has a joint depth of at least 30mm and a joint width of at least 8mm. As can be seen in the graph, the correct joint has a chimney shape: the joint width is the same across the entire depth. This joint shape guarantees optimum joint rigidity.

With optimum statics, the joint can withstand physical and thermal stresses (camber stress, bending and tensile forces, etc.) in accordance with the relevant regulations for road and rail traffic. Withstand road construction. The decisive factor is also the correct substructure (see technical information). If you have small deviation in the joint width and joint depth this is not a problem. However, at least 80% of the total area of the measures should be respected.

Mainbrick pavement joint mortar should, as shown in the diagram, be chimney-shaped joints with min. 30mm depth and 8mm width are slipped. If the Mainbrick paving mortar is used in other conditions, it can lead to problems such as joint cracking, cracking of the joints, softening of the joint due to waterlogging etc. The following graphics show incorrect applications of grouting materials (not only Mainbrick pavement grout, no solid grout may work if used incorrectly).

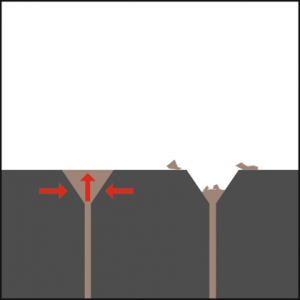

Problem 1: Stones with V-shaped joints

For stones whose sides are beveled, V-shaped joints are created. The V-shaped joints do not offer the necessary chimney shape for joint static analysis (see picture 1). When pressure comes on the stones, she pushes out the V-shaped joint upwards for lack of statics. The fugue breaks and begins to crumble. In addition, the drainage of water is limited possible because the lower part of the joint is too narrow. Waterlogging can cause the joint to soften.

Problem 2: Stones with grabber cams

There are concrete blocks that have grabber cams. These cams are on the stone side over the entire depth of the stone (marked red in the graphic). These cams make it impossible to maintain the minimum width. The necessary joint statics is not reached and thus the joint can tear and crumble. WARNING: Grab nocks do not give a gap! They serve only to protect the transport of the stones. The minimum distance of 8mm must always be observed! The graphic shows stones with grabber cams from above and from the side (marked in red).

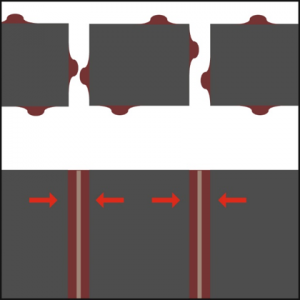

Problem 3: Stones with ornamental joints

There are concrete blocks with ornamental joints, which are only large at the top and very narrow down below. This bending of the stones leads to a tulip (or wineglass) form of the joint. These tulip-shaped joints do not offer the required joint geometry. Various problems arise:

- Thermal: Stones heat up, surface is cold, stones bulge upwards (arch tension).

- At the „tulip neck“ creates a predetermined breaking point. Once by bending u. Tensile pressure is exerted on the joint, breaking it here

- Rounded sides favor breaking off as soon as the joint is loaded.

The graphics show the problems that arise with ornamental joints.

You can see that there are very different and different types of stone, so it should look closer to the grouting something which joint width and joint depth there. Because we from the Mainbrick team also offer a plaster joint mortar for very narrow joints. From a width of 3mm joint width you can also use our special Mainbrick paving joint mortar. Just have a look at our other blog post.